Sustainability and circular economy in AMS

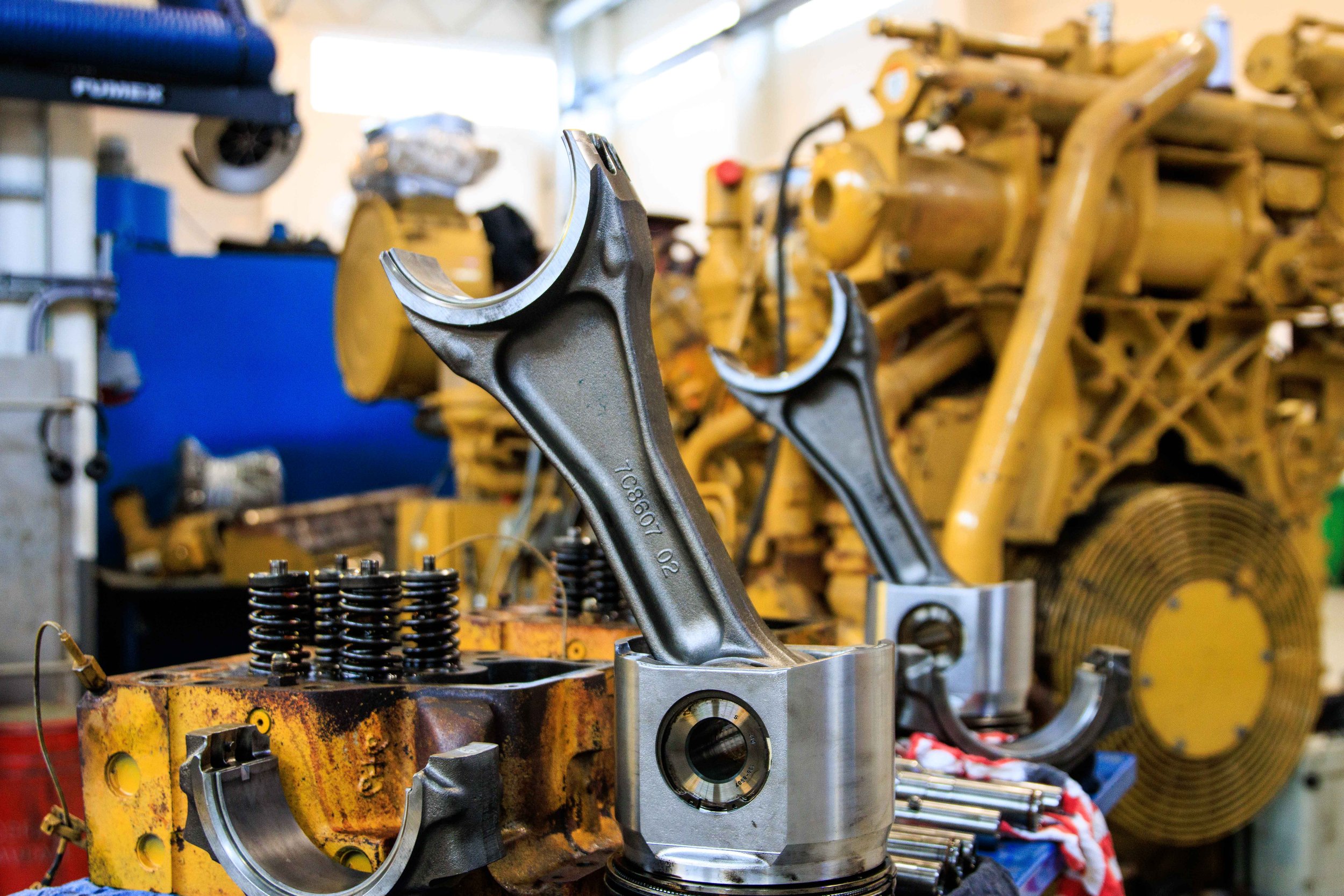

We specialize in maintenance, repair and modification of engines for maritime, marine, petroleum and land-based industries. Through maintenance and repair, we contribute to optimal operating conditions and maximize the service life of engines in operation.

Our sustainability promise is to make things last and work - for a long time.

This is a fundamental element of the circular economy - to use the resources that have already been used for as long as possible.

AMS is, and has always been, a circular economy company.

To ensure the customer good quality in products and services, we only use original OEM parts in our deliveries. Some of these are brand new, while others are reconditioned used parts (reman - re-manufacturing) supplied by the manufacturer. At our premises, we also overhaul a large amount of used parts for reuse. These include cylinder heads and valves, turbos, diesel pumps, cylinder liners and injectors. We have a large amount of used overhauled parts in stock at all times, available to customers at short notice. We do the same with used engines, overhauling them and refurbishing them for new and extended service life. Our extensive international network means that we can make most engines available to our customers in used and reconditioned condition.

We also operate a deposit system for parts. These are parts that can be overhauled and then used again. The way it works is that when we deliver a new or reconditioned part to a customer, it is sold with an added value for a deposit (in the same way as when you buy a bottle of mineral water). We take in the old part and if it can be overhauled, the customer will get the deposit back. We then overhaul this part and put it in stock, ready for delivery to the next customer.

AMS helps to reduce greenhouse gas emissions by supplying and installing SCR (Selective Catalytic Reduction) systems. These systems reduce NOx emissions to the atmosphere to the limits set by the authorities. We also convert engines from one generation of emission requirements to the next generation. This is a system set up by the IMO (International Maritime Organization) to reduce greenhouse gas emissions from diesel engines. There is a set of requirements for the different levels (Tier) that must be achieved in order for the engine to be approved to the relevant level.

We have two buildings from which we run our business, in Tananger and Ågotnes. Both of these are constructed according to strict building requirements and are very energy efficient. All our waste is sorted at source and delivered for recycling and/or special handling. For example, all scrap metal is sent for recycling. Both buildings have efficient oil separators that prevent emissions to the external environment. Our activities entail the necessary use of some chemicals. We always strive to use the least environmentally harmful products on the market.

AMS helps ensure that the resources used last as long as possible, in the most (energy) efficient way possible. This benefits our customers and our society. We are and will remain a circular economy company with a strong focus on reuse, continuous improvement and (energy) efficient solutions.